Product enquiry

"*" indicates required fields

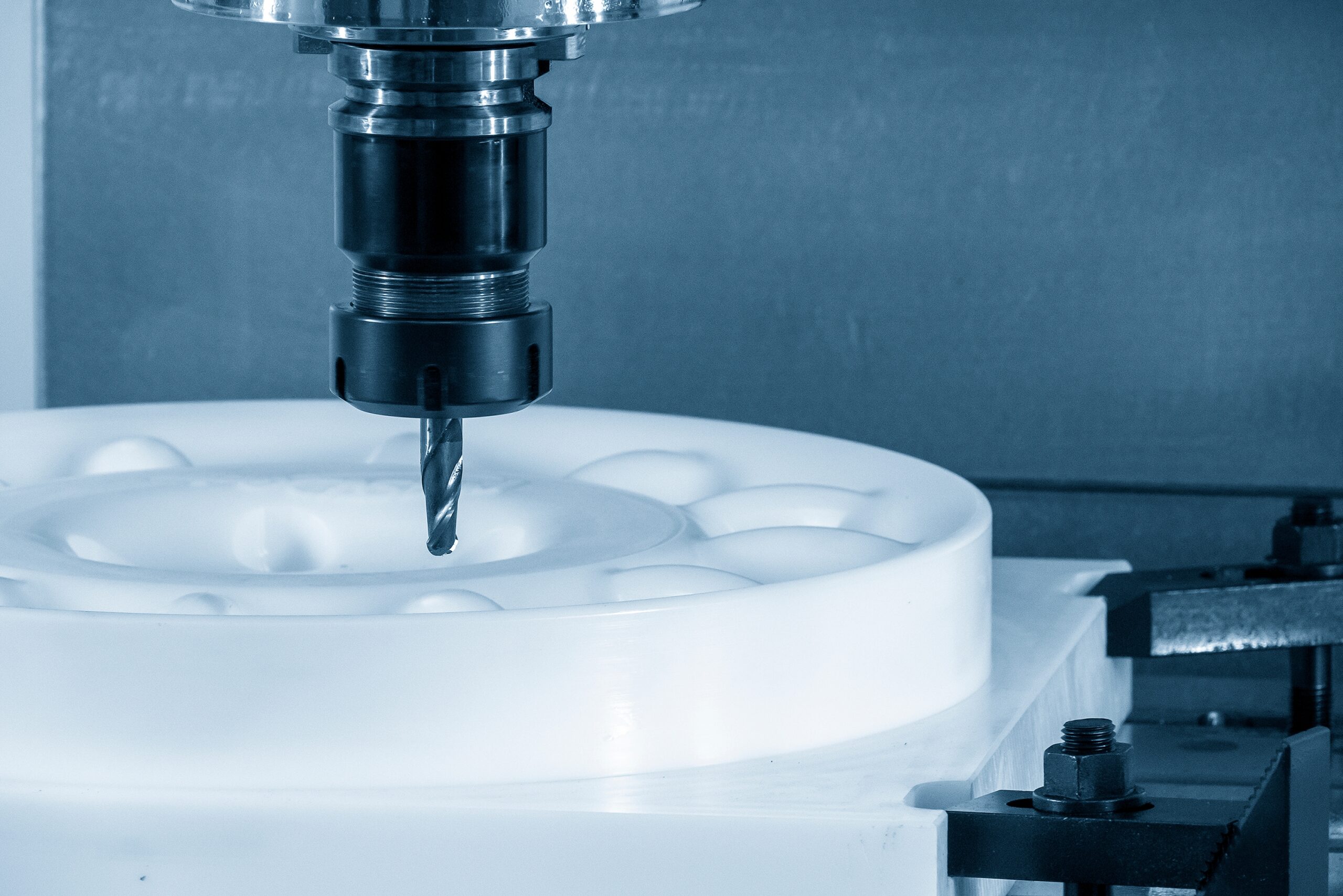

Customer-specific molded parts can be manufactured according to reference samples, customer drawings and our own design and development according to the installation situation and application parameters.

The molded parts can be made from various elastomers or thermoplastics. Various qualities are available for this. The production of elastomer metal connections (2K parts) is just as possible as the production of small series, hand samples for internal tests from pilot tools and large series.

are made from compression-molded pieces of tubing and cut to height. This results in a press-smooth inner and outer surface and an absolutely sharp-edged design with tight tolerances.

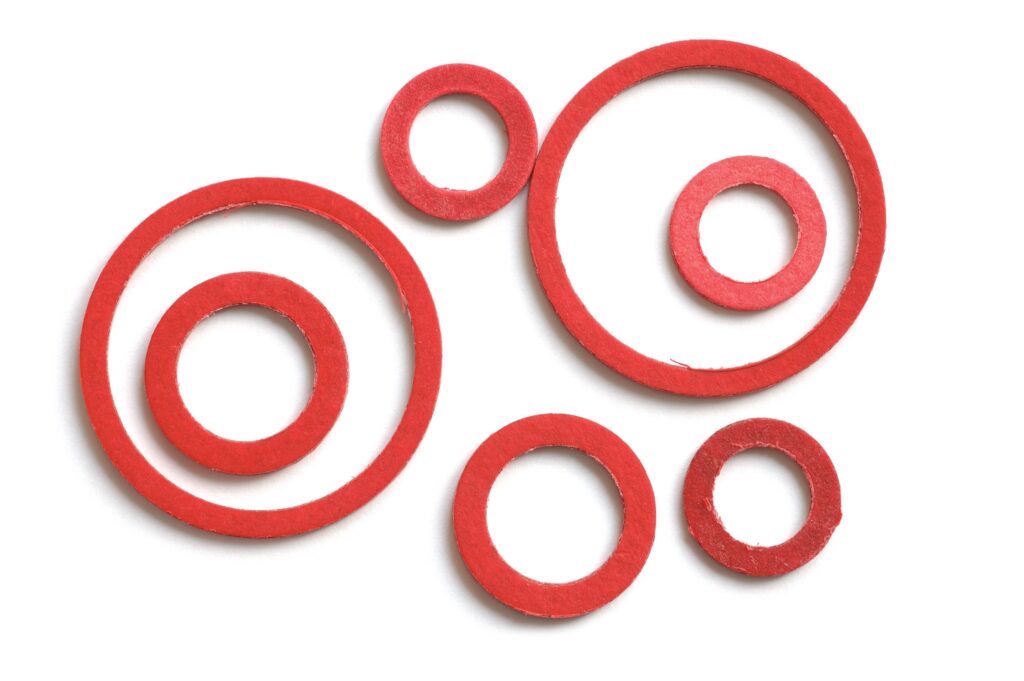

Very small parts manufactured with high precision from:

·Steel strip cutting tool

·Knife cutting tool

·Free cut tool

·Complete cutting tool

·Consecutive cutting or progressive compound tool

·Narrow tolerances possible

Main function: Seals against media, air, dust, liquids, …

· Rubber elastomers

· High pressure materials

· Rubber cork

· Foams

· Graphite

· Plastics

· Beading metal

· Membrane materials

· Paper/fiber base

– Liquid silicone

Advantages: no rework necessary, very good surface quality

Disadvantages: high investment in tools, only economical if large quantities are required

are mainly used in dosing, regulating and control devices. Precise technical coordination is required as to whether a standard membrane with the appropriate beading, a rolling membrane or a fabric-reinforced membrane should be used.

Since restoring forces, lifting height, damping effect, pressure differences, avoidance of sharp edges and other factors also need to be taken into account, technical advice is recommended.

Made from sheet material can also be used, among other things

self-adhesive film.

PA-SEALS:

Seals made of polyacrylate (PA) are used at high ambient pressures and fulfill similar functions to support rings.

FEP parts:

The encapsulated O-ring is protected from chemical influences by the FEP jacket. The core can be made of FPM or VMQ.

PTFE-SEALS:

PTFE parts include O-rings and support rings in different designs, as well as drawing-based molded parts.

A large part of our product portfolio is made up of drawing-based molded parts that we develop and produce in collaboration with our customers.

This also involves material selection and critical special tolerances.

"*" indicates required fields